Foam Die Cutting Manufacturers in Pune, Suppliers in Pune, Mumbai, Chakan, Shirwal, Ranjangaon, Aurangabad (Sambhaji Nagar)

Adwait industries leading foam die cutting manufacturers in Pune, suppliers, dealers in Pune, Mumbai, Shirwal and Chakan, Ranjangaon, Aurangabad (Sambhaji Nagar). We are proud to provide our advanced solutions that accuracy, adaptability and creativity.

Foam Die Cutting in Pune, Mumbai, Ranjangaon, Aurangabad (Sambhaji Nagar) :

As leading foam die cutting manufacturers, Foam die cutting is a specialised manufacturing technique that includes cutting foam materials into exact shapes and sizes with custom-made dies. This process provides consistency and accuracy in every cut, making it a great alternative for applications that need precision and complicated patterns. Our foam die cutting services accommodate a wide range of foam materials, including polyurethane foam, polyethylene foam, and others.

Features of Foam Die Cutting:

- Accuracy Cutting: As top foam die cutting suppliers, our foam die cutting services prioritize exceptional accuracy. Our state-of-the-art technology, along with precise die design, guarantees that each cut is accurate, fulfilling the dimensions and tolerances necessary for the most demanding applications.

- Versatility in Foam Materials: Our foam die cutting services can handle a variety of foam materials, including soft and malleable polyurethane and denser and stiff polyethylene. This adaptability enables us to meet the particular requirements of numerous sectors and applications.

- Complex and Intricate Designs: Being top Die Cut Foam dealers, our Foam die cutting is ideal for detailed and complicated patterns. Whether you need complicated patterns for package inserts, custom-shaped gaskets, or precisely cut foam components for industrial purposes, our services can bring your vision to life with meticulous precision.

- High Production Efficiency: As leading foam die cutting manufacturers, our foam die cutting services are intended to maximize production efficiency. The automated nature of the process provides quick and accurate cuts, making it appropriate for large-scale manufacturing while maintaining the precision necessary for each component.

Advantages of Foam Die Cutting:

- Uniformity Across Production cycles: Foam die cutting has the benefit of maintaining uniformity during production cycles. Whether you're making a few prototypes or mass-producing components, each cut is the same, assuring consistency in the finished result.

- Cost-Effective Solution: As Foam Die Cuts suppliers our Foam die cutting is a cost-effective option for enterprises that need precision-cut foam components. The process's efficiency, paired with its capacity to handle huge production numbers, leads to labour and material cost reductions.

- Waste Reduction: Precise foam die cutting reduces material waste. By optimising the positioning of cuts on foam sheets, we can increase material utilization, reduce scrap, and contribute to a more sustainable and cost-effective production process.

- Customisation for Various Applications: Being foam die cutting dealers, our foam die cutting services provide extensive customisation options. Whether you need bespoke packaging solutions, automotive components, medical inserts, or elaborate designs for the arts and crafts sector, we can adapt our services to match your individual needs.

Applications of Foam Die Cutting:

As foam die cutting manufacturers in Pune, Ranjangaon, Aurangabad (Sambhaji Nagar) our products are used in the following sectors:

Packaging Inserts

Foam die cutting is often used for creating personalized package inserts. The precision-cut foam inserts safeguard sensitive electronic components, delicate medical gadgets, and sophisticated parts of machinery during shipping and handling.

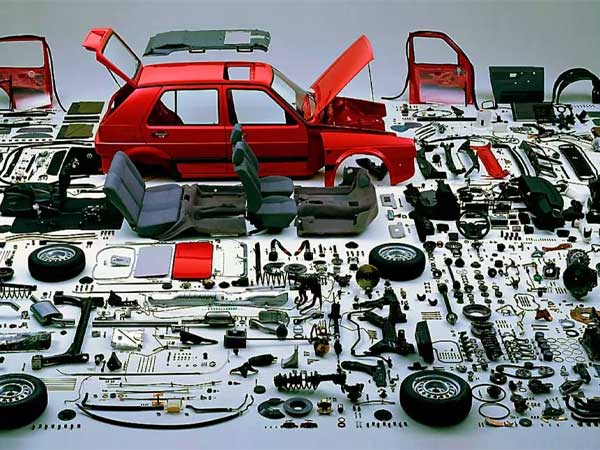

Automotive Components

As foam die cutting suppliers, our Foam die cutting is used in the automotive sector to create specialised gaskets, seals, and insulation components. The ability to precisely cut foam materials enables the creation of components that integrate easily into complicated automobile systems.

Healthcare

foam die cutting is essential for generating precise inserts for medical device packaging. The custom-fit foam offers cushioning and protection, protecting the devices' integrity throughout travel and storage.

Industrial

Being a foam die cutting dealers our Foam die cutting is used in industrial insulation to make accurate components. These components may be designed to match specific machinery or equipment, providing thermal and acoustic insulation as required.

Our foam die cutting services combine precision, adaptability, and efficiency. Whether you work in packaging, automotive, medical, or industrial manufacturing, our foam die cutting solutions provide a dependable way to accomplish elaborate patterns and exact cuts in foam materials. Choose Adwait Industries leading foam die cutting manufacturers, suppliers, dealers in Pune, Mumbai, Shirwal, Chakan, for a cooperation that produces unprecedented outcomes, improving the quality and precision of your foam components.

Adwait Industries

Adwait Industries